What Is Insulating Material in Cable?

Posted : 28-February-2024

In the realm of cable manufacturing, the insulating material plays a crucial role in ensuring the safety and reliability of electrical systems. Understanding what insulating material is and its significance is fundamental for anyone involved in the design, installation, or maintenance of cables.

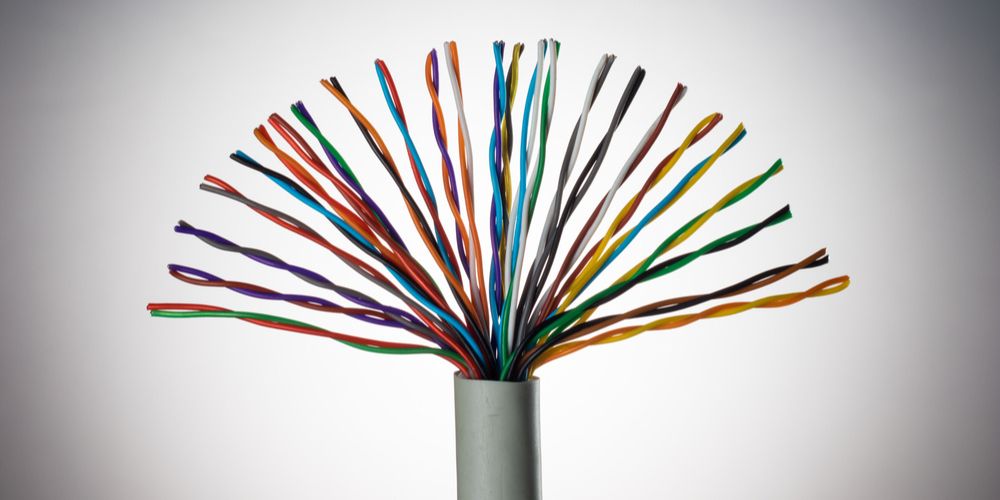

Introduction to Insulating Material in Cable

Insulating material serves as a protective barrier between conductive elements within a cable. Its primary function is to prevent electrical current from leaking out, thus maintaining the integrity of the electrical circuit and safeguarding against electrical hazards such as short circuits and electrical fires.

Types of Insulating Materials

Rubber

Rubber was one of the earliest materials used for insulation due to its flexibility and resistance to high temperatures. However, its usage has declined with the advent of synthetic materials offering superior properties.

PVC (Polyvinyl Chloride)

PVC is a widely used insulating material known for its affordability, flexibility, and resistance to moisture and chemicals. It is commonly found in household wiring and low-voltage applications.

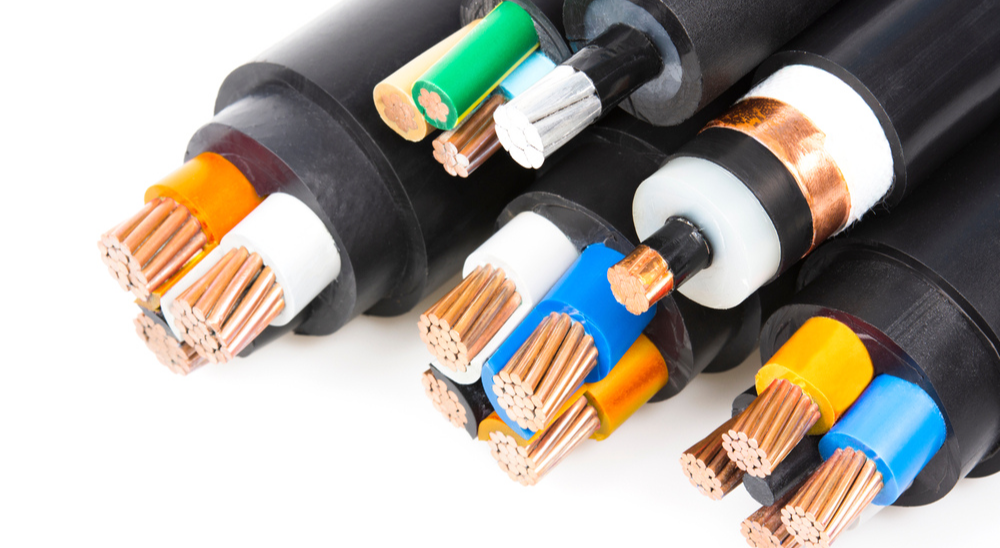

XLPE (Cross-Linked Polyethylene)

XLPE, renowned for its excellent electrical properties, high-temperature resistance, and mechanical strength, frequently serves in high-voltage power cables and underground transmission lines.

Properties of Insulating Materials

Insulating materials possess several key properties that determine their suitability for specific applications:

Thermal Stability

Insulating materials must withstand elevated temperatures without degradation to maintain their effectiveness in high-temperature environments.

Electrical Insulation Properties

Effective insulation materials exhibit high dielectric strength, preventing the flow of electrical current and minimizing losses in transmission.

Mechanical Strength

Insulating materials should possess sufficient mechanical strength to withstand installation stresses and external environmental factors without compromising their integrity.

Importance of Insulating Material in Cables

The importance of insulating materials cannot be overstated in ensuring the safety, efficiency, and longevity of electrical systems. Without proper insulation, the risk of electrical failures, equipment damage, and safety hazards significantly increases.

Applications of Insulating Materials in Cables

Insulating materials find applications across various industries, including power generation, telecommunications, automotive, and aerospace, where reliable electrical insulation is paramount.

Challenges in Insulating Material Selection

Selecting the appropriate insulating material involves considering factors such as environmental conditions, voltage ratings, mechanical requirements, and regulatory compliance, posing challenges for engineers and designers.

Innovations in Insulating Materials

Ongoing research and development efforts continue to yield innovations in insulating materials, focusing on enhancing performance, sustainability, and cost-effectiveness.

Future Trends in Insulating Materials for Cables

We expect future trends in insulating materials to emphasize sustainability, recyclability, and compatibility with emerging technologies such as renewable energy and electric vehicles.

Environmental Impact of Insulating Materials

The environmental impact of insulating materials, particularly those containing hazardous substances such as PVC, raises concerns regarding their disposal and long-term sustainability.

Regulations and Standards Governing Insulating Materials

Various regulatory bodies and industry standards govern the manufacturing, testing, and use of insulating materials to ensure compliance with safety and performance requirements.

Factors Influencing the Choice of Insulating Materials

Factors influencing the choice of insulating materials include electrical properties, temperature ratings, environmental considerations, cost, and availability.

Best Practices for Handling Insulating Materials

Adhering to best practices for handling insulating materials is essential to prevent damage, contamination, and safety hazards during storage, transportation, and installation.

Testing and Quality Control of Insulating Materials

We employ stringent testing and quality control measures to assess the electrical, mechanical, and thermal properties of insulating materials, ensuring they conform to specifications and standards.

Related Topics of Ethernet Cables

Ethernet cables, pivotal for modern networking, are intertwined with crucial related topics. These include cable categories (Cat5e to Cat7), shielding against electromagnetic interference, cable lengths’ impact on performance, and termination techniques. Understanding these aspects is vital for deploying efficient networking solutions.

- Benefits of Ethernet Cables: Cat5e, Cat6, Cat6a, and Cat7

- 5 Vital Steps to Establishing an Office Ethernet Cable Network

- How to Make Ethernet Cables?

- The Latest Trend in the Category Cables

Frequently Ask Questions

What are the main types of insulating materials used in cables?

Rubber, PVC, and XLPE are among the main types of insulating materials used in cables.

Why is thermal stability important in insulating materials?

Thermal stability ensures that insulating materials can withstand elevated temperatures without degradation, maintaining their effectiveness in high-temperature environments.

How do regulations govern the use of insulating materials?

Regulations and standards govern the manufacturing, testing, and use of insulating materials to ensure compliance with safety and performance requirements.

What are the challenges in selecting insulating materials for cables?

Challenges in selecting insulating materials include considering factors such as environmental conditions, voltage ratings, mechanical requirements, and regulatory compliance.

What are the future trends in insulating materials for cables?

Future trends in insulating materials emphasize sustainability, recyclability, and compatibility with emerging technologies such as renewable energy and electric vehicles.

Conclusion

Insulating materials play a vital role in ensuring the safety, reliability, and efficiency of electrical systems. Understanding the types, properties, and applications of insulating materials is essential for making informed decisions in cable design and installation.

Latest Blog

-

Cat5e, Cat6, Cat6a and Cat7: Ethernet Cable Differences and Similarities

Read More -

Category Cable Services in USA

Read More -

Structured Cabling Standards For Commercial Buildings

Read More -

Evolution Of Ethernet Cables: Cat5e vs Cat6

Read More -

Select the Right Shielded Cable for your Network

Read More -

How To Decide on The Right Cables for Your Business Network

Read More -

What is Category 6 Cable?

Read More -

Why You Should Choose Cat6 Plenum Shielded?

Read More -

What Is Insulating Material in Cable?

Read More -

What Are The Cat5e And Cat6 Cable Testers?

Read More