How to Make Ethernet Cables?

Posted : 1-January-2024

Introduction to Making Ethernet Cables

Ethernet cables serve as vital components in networking, facilitating seamless data transmission within local area networks (LANs). While makeup cables are readily available, mastering the art of crafting your own offers many benefits, including customization, cost efficiency, and an enhanced understanding of network infrastructure.

Exploring Ethernet Cable Varieties

Ethernet cables come in several types, to each designed to meet exact networking requirements. Among the most public are CAT5e, CAT6, and CAT6a. CAT5e serves as a versatile option suitable for most residential and small-scale business networks, whereas CAT6 and CAT6a plenum make available superior bandwidth and speed, ideal for demanding applications such as video streaming and gaming.

Essential Tools and Materials

Before getting on your Ethernet cable crafting journey, make sure you have the following tools and materials at your disposal:

- Ethernet cable (CAT5e, CAT6, or CAT6a)

- RJ45 connectors

- Crimping tool

- Cable cutter/stripper

- Optional: Cable tester for quality assurance

- Step-by-Step Guide to Creating Ethernet Cables

Get ready and Stripping the Cable: Begin by measuring and cutting the desired length of Ethernet cable using a cable cutter. Make use of a cable stripper to carefully remove approximately 1.5 inches of the outer jacket, exposing the inner wires.

Aligning Wires to the Right Sequence: Untwist the wire sets and arrange them according to the T568B wiring standard, confirming the correct color sequence: orange-white, orange, green-white, blue, blue-white, green, brown-white, brown.

Securing Cable Termination: Insert the arranged wires into the RJ45 connector, and make sure they reach the end of the connector. Utilize a crimping tool to firmly secure the wires in place by exerting even pressure on the connector.

Verifying Cable Functionality

After crimping both ends of the cable, it’s imperative to test its functionality using a cable tester. This ensures that the cable is correctly terminated and capable of transmitting data without errors, thereby assuring optimal network performance.

Avoiding Common Pitfalls

Incorrect Wiring Sequence: Adhere strictly to the T568B standard to ensure compatibility with most networking equipment.

Excessive Crimping Pressure: Avoid applying excessive pressure when crimping connectors to prevent damage to the cable or connectors.

Overly Untwisted Wires: Maintain the twist of wire pairs as close to the connector as possible to minimize crosstalk and interference.

Advantages of Crafting Personalized Ethernet Cables

Cost Efficiency: Crafting your own Ethernet cables often proves more economical than purchasing pre-made options, particularly for longer lengths. Additionally, setting up an ethernet cable network can enhance connectivity and reliability in your home or office environment.

Customization: Tailor the cable length to specific networking requirements, reducing unnecessary cable clutter and optimizing space utilization.

Educational Value: Gain valuable insights into networking principles and cable termination techniques, fostering a deeper understanding of network infrastructure.

Conclusion

Mastering the art of crafting Ethernet cables empowers individuals to create custom network solutions tailored to their unique needs. By following established techniques and standards, DIY enthusiasts can reap the benefits of cost efficiency, customization, and enhanced knowledge of networking fundamentals.

FAQs

Can I utilize any Ethernet cable for crafting my own cables?

While technically feasible, it’s advisable to opt for CAT5e plenum, CAT6, or CAT6a cables to ensure optimal performance and compatibility with networking equipment.

Do I require specialized tools for crafting Ethernet cables?

Yes, essential tools include a cable cutter, stripper, crimping tool, and optionally, a cable tester for quality assurance purposes.

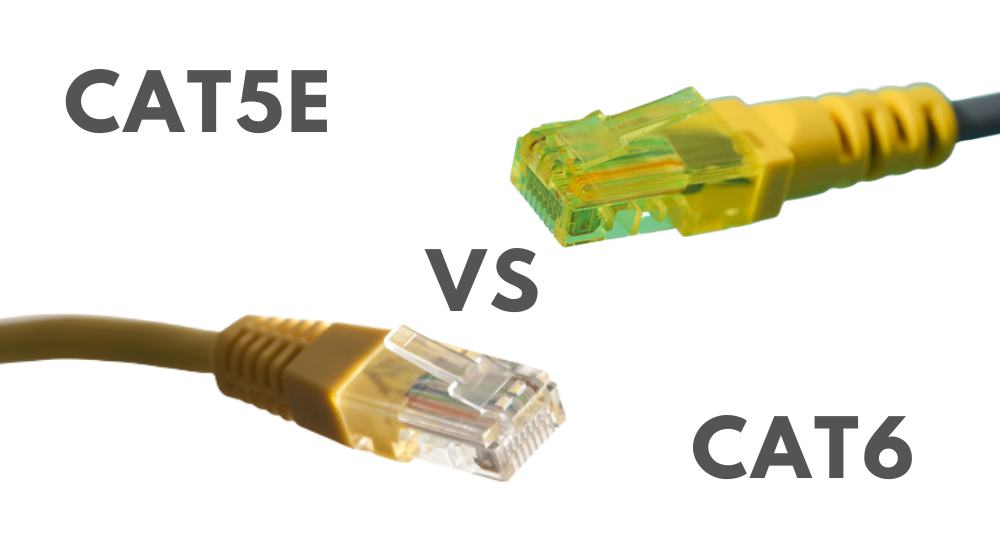

What is the Difference Between CAT5e and CAT6 Plenum Cables?

CAT6 plenum cables offer higher bandwidth and faster data transmission rates than CAT5e, making them suitable for more demanding networking applications.

How can I ascertain whether my Ethernet cable is correctly terminated?

Employ a cable tester to verify continuity and ensure all wires are properly connected without any shorts or miswires.

Are there any safety precautions to consider when crafting Ethernet cables?

Exercise caution when using cutting and crimping tools to mitigate the risk of injury. Additionally, remain mindful of electrostatic discharge (ESD) when handling sensitive networking equipment.

Latest Blog

-

When Should You Upgrade Your Internet Cable?

Read More -

What You Need to Know for Safe Networking

Read More -

Why Ethernet Cables Are Crucial for Commercial Areas

Read More -

Category Cables Plenum Safe and Efficient Networking

Read More -

How Cat6 Plenum Cable Enhances Your Gaming Experience

Read More -

Cat5e, Cat6, Cat6a and Cat7: Ethernet Cable Differences and Similarities

Read More -

Category Cable Services in USA

Read More -

Structured Cabling Standards For Commercial Buildings

Read More -

Evolution Of Ethernet Cables: Cat5e vs Cat6

Read More -

Select the Right Shielded Cable for your Network

Read More